Described as the “construction site of the century”, securing and then restoring the cathedral promised to be complex in the aftermath of the devastating fire of 2019. Initially, the priority was to consolidate the parts that were in danger of collapsing and to dismantle the scaffolding from previous work. This stage has just been completed and the restoration phase will at last begin.

To quickly restore its splendour to Notre-Dame de Paris, the use of new technology has played and will play a central role. Today, we invite you to review the current situation of the works and the way in which the most recent digital technology is helping to carry out this historic project.

15 April 2019: Notre-Dame de Paris was devastated by a fire of rare intensity. While undergoing major restoration work, the Gothic cathedral, more than 850 years old, was destroyed by a violent fire. It lost its spire, its roof, its clock and part of its vault, damaged by the flames, creating a wave of emotion across the globe.

In the early morning of 16 April, once the fire had finally been brought under control, the cathedral was still standing, but the work to secure the building and restore it was considerable. Emmanuel Macron's desire to reopen the cathedral in 2024 left professionals in the sector perplexed, for financial reasons of course, but also because of the lack of artisans in France and Europe.

A colossal project bringing into play multiple skills

The day after the fire, securing and consolidation work – essential before the reconstruction phase – began on this jewel of Gothic architecture.

This first phase was to dismantle the scaffolding that was in place during the fire, remove the great organ and the cleaning test sites in two chapels, install wooden arches under the flying buttresses and clear and sort the remains and secure the crossing of the transept. It involved many trades and a vast range of expertise, including stone/masonry, sculpture, stained glass, carpentry, roofing, wood joinery, locksmithing, ironwork, wall painting, metal, cleaning of lead and lead constraints, scaffolding, etc.

This diversity is explained by the scale of the work site as well as the various complications it may have experienced since the incident.

Technology-powered site

If the fire that destroyed the roof of Notre-Dame had occurred ten years earlier, it is not sure that the cathedral would have survived. Technology was used from the first minutes of the disaster and has continued to support the operational teams at all times since then.

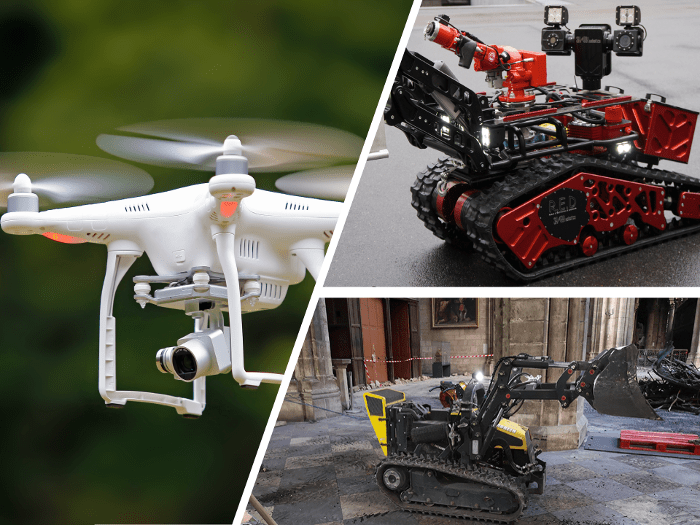

From the start of the fire, several drones equipped with cameras were deployed by the police prefecture in the Parisian sky. The images of the fire “seen from above” were transmitted to the fire service headquarters to gain better understanding of the devastation and, above all, of the spread of the fire, in order to adjust the operational response of the teams on the cathedral square. This overview would have been impossible to obtain without the use of drones...

On the ground, the Paris fire-fighters deployed an extinguisher robot inside the nave both to put out the fire but also to lower the temperature in the building. Remote-controlled and thanks to its tracks, Colossus - that's its name - was able to cross debris and obstacles to move through the heart of the fire by pulling up to 250 metres of pipes filled with water.

Of course, the work of the drones and robots did not stop once the flames were extinguished and this digital support continued to be used to secure the cathedral. In the days immediately following the fire, the roof could have collapsed at any time and the teams could not circulate inside Notre-Dame. Drones were therefore used to draw up an image inventory of the cathedral and map the premises in 3D.

Several months later, with the vault still threatening to collapse, some areas were still not accessible. 4 robots therefore were tasked with helping to clear the rubble from the building. Robots mounted on tracks, remote-controlled with features adapted to this unique site: a grapple bucket for transporting the heaviest and bulkiest pieces of stone and wood, shears for cutting metal scaffolding, and even a broom to clean the cleared surfaces.

To allow the various trades to work together in collaborative mode and in optimal safety conditions, given the dimensions and characteristics of the cathedral, the teams of the many contractors involved in securing Notre Dame also use digital tools.

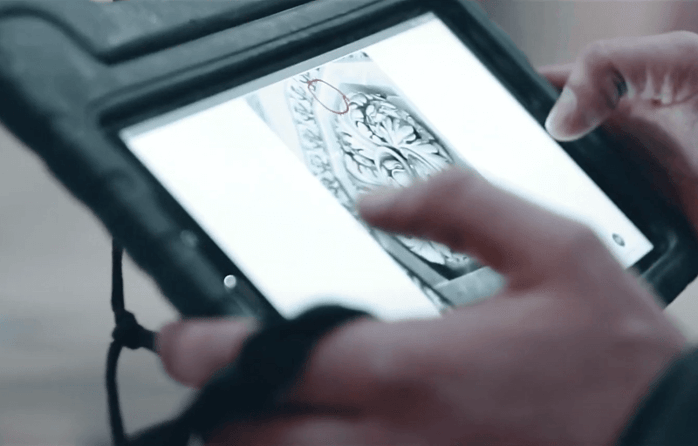

To begin with, to help the various trades working on the site, a BIM (Building Information Modelling) model was created. This digital twin is based on a 3D digital pre-fire model enriched by post-fire surveys, including more than 40,000 photos / thermal images and 400 high-precision panoramic shots taken by drones. This collaborative and scalable database allows site stakeholders to benefit from and share in real time all the information needed to ensure smooth running of operations.

Digital, mobile and innovative solutions are also used by some stakeholders. This is the case for the Jarnias teams. The contractor, a French leader in work at height for major construction projects, arrived on the scene a few days after the fire. Its mission was to help evacuate the rubble from above (a particularly delicate operation due to the fragility of the cathedral) and to install safety nets to catch any falling objects. Tarpaulins were also deployed to protect the building from the rain. Finally, during this first securing phase, Jarnias also got down to dismantling the burned scaffolding.

To help its teams work on such prestigious, complex and demanding projects as Notre-Dame de Paris, Jarnias chose the Finalcad site monitoring platform. This is a collaborative platform dedicated to construction, renovation and maintenance professionals. It optimises the times, costs and efficiency of on-site operations, in particular thanks to the possibility of collaborating in real time, via mobile terminals and in difficult conditions, for example when teams are suspended several metres above ground.

What is the status of the project today?

More than two years after the fire, donations continue to flood in to fund the work. General Jean-Louis Georgelin, president of the public establishment responsible for the restoration of Notre-Dame, announced that 840 million euros had already been collected.

At the “Village des Métiers” installed on the cathedral square, during the 38th European Heritage Days, on 18 September 2021, he declared: “today [...] we have completed the consolidation phase of Notre-Dame which is no longer in danger of collapsing and we are entering the actual restoration and reconstruction phase”. He also announced that Notre-Dame de Paris would be reopened for worship in 2024.

The Public Establishment is now preparing to launch calls for tenders to select the contractors that will take part in the restoration project scheduled for the end of the year.

Of course, for this new phase of reconstruction, digital technology will still play a key role:

1) To facilitate collaboration between the workers of the different trades involved. On this type of project, spanning several years, digital technology contributes to the sharing of information between very large teams who have usually never worked together before.

2) To allow more adaptability and creativity for this unique project. The topology of the construction site is atypical and there are numerous constraints linked to the preservation of what already exists in the cathedral. The methods, tools and practices used will have to be adapted and will not be the same as on a new construction or conventional rehabilitation site. Thus, for example, in this "constrained" environment, the work will be done from paperless plans to save considerable space, time and efficiency.

3) To meet deadlines announced for the reopening of the cathedral for worship in 2024.

Are you looking for tools to digitise your worksites?

Let's talk about this together.